Instructions for use

Flexible hoses

Instructions common to flexible hoses and bellows

-

These products are made from thin plates. Even insignificant impact may damage the products.For transportation, pack them with sufficient packaging materials, and handle them carefully during transportation.

-

Store the products in a clean and dry room. Avoid contact with high moisture, saline matter and highlyacid atmosphere.

-

Use them in the ranges specified in drawings, delivery specifications and catalogs.If any product is used out of the design specifications, it may be damaged.

-

Avoid using fluids which do not have corrosion resistance for each material.

-

Do not expose the products directly to sparks from a welder or a grinder.When using a welder or a grinder near the products, appropriately protect them.

-

If they are moved after installation or used as measures against vibration, fatigue cracks may develop in them in a short period.

Flexible hoses

-

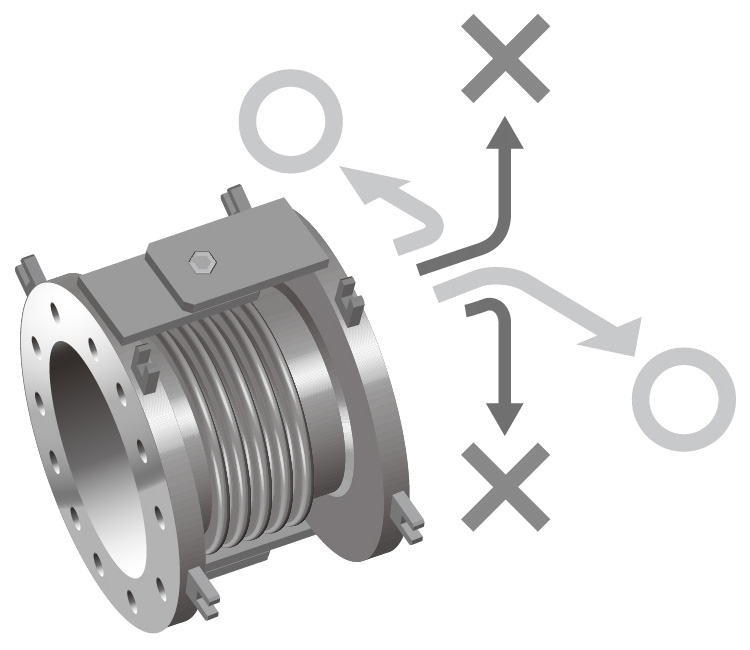

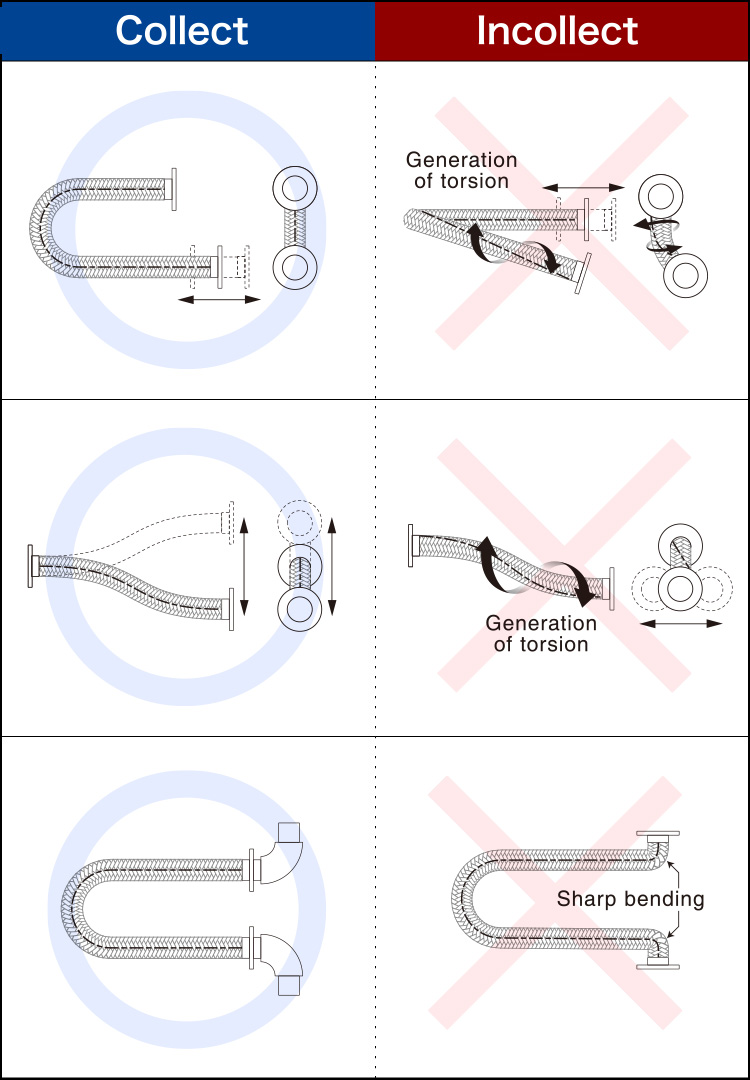

When installing any flexible hose, do not apply torsion to it.

To prevent damage owing to torsion during installation, it is recommended to use a joint, such as a loose flange,union joint or SNM joint, which can prevent torsion at one end of the tube.

-

Do not install any flexible hose in such a way that the tube is twisted when it is bent.

Install the tube in such a way that it is constantly on a certain plane to prevent damage to the tube caused by torsion when it is bent.

-

Avoid bending any flexible hose at a sharp angle.

If a tube is installed improperly, the tube may be repeatedly bent at a sharp angle. If a tube is used at a radius lower than the allowable minimum bending radius, it will be fatigued early and damaged in a short period.

-

Do not expand or contract any flexible hose.

Do not install a tube in an expanded or contracted condition exceeding the specified range.

-

Reworking

Avoid reworking any joint if possible. When reworking a joint, take care not to damage the hose or joint, and protect the hose to prevent entry of dust into the tube.

-

Welding

When welding a hose to a mating pipe joint, take utmost care that the hose is not thermally influenced. Otherwise, it may be distorted, or the material characteristics may be degraded, thereby resulting in early breakage.

-

Examples of correct use and incorrect use

Bellows

Bellows

-

When carrying

When lifting up and down bellows, fit a patch to the pipe zone, wind a wire rope around it, and lift the bellows.Do not wind a rope around the bellows, bellows protective cover, set bolt or guide rod.

-

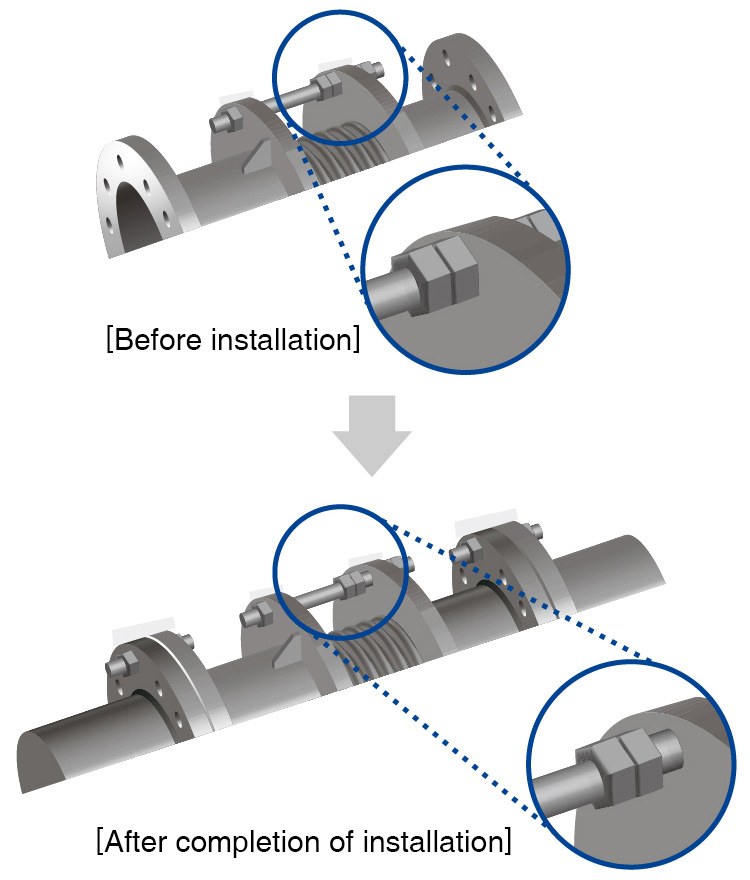

Set bolt

Bellows are provided with a set bolt for transportation and size adjustment. After the completion of installation of the bellows, remove the set bolt without fail before performing the pressure resistance test.

-

Guide rods/tie rods

Guide rods/tie rods have been installed according to the design specifications. Do not loosen or tighten the nuts.The nuts to be adjusted after the completion of installation shall be adjusted as specified on the drawing.

-

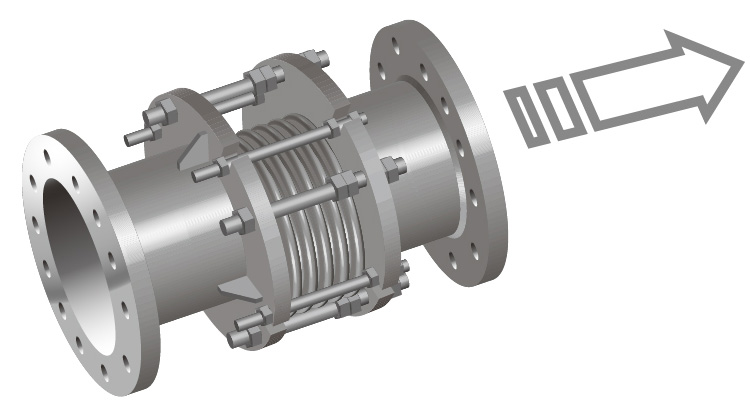

Flowing direction

Bellows are marked with an arrow if the flowing direction through the bellows has been determined. Install such bellows in the indicated direction.

-

Hinge type expansion joint (p.65)

The hinge type joints can absorb only angular displacement in a plane. When installing them, check carefully the hinge plate direction.